Sabae technology

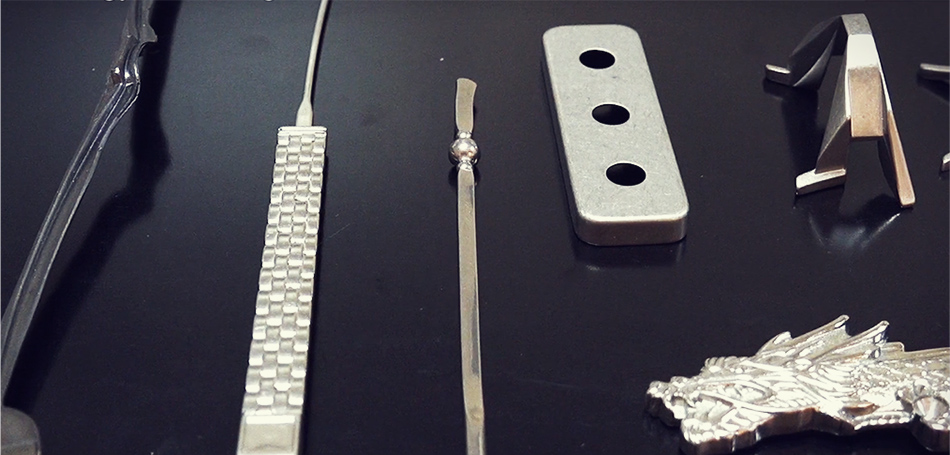

Sabae is full of traditional making

and one of Japanese leading technology

industrial city:

including

eyeglasses that have

the largest production share in Japan,

Echizen lacquerware,

which accounts for 80% of

the domestic production share of

lacquerware for business,

textile of Sabae, known as the center of

textile kingdom FUKUI.

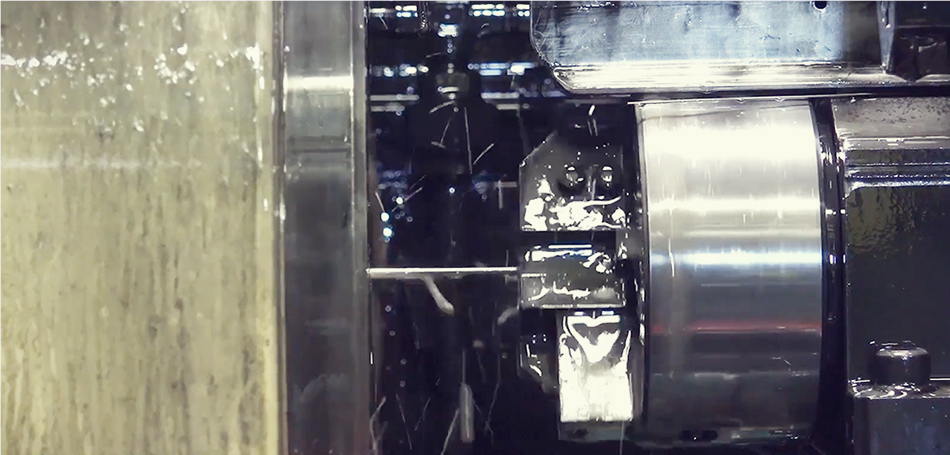

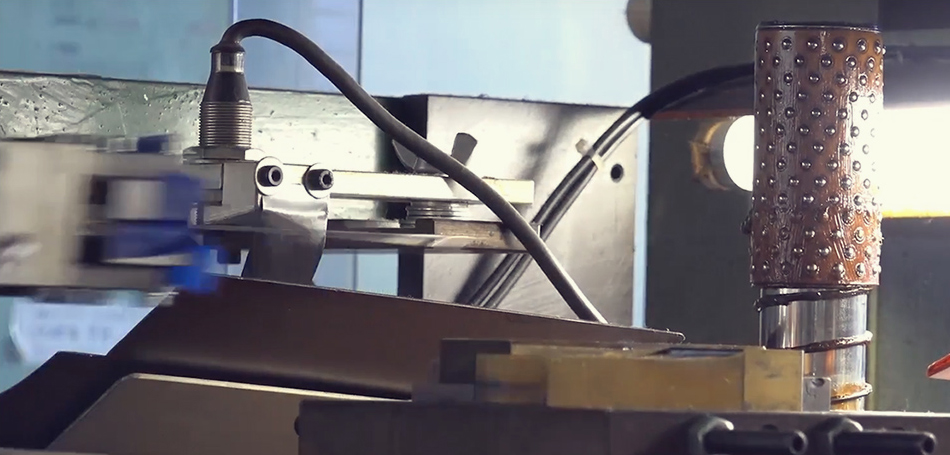

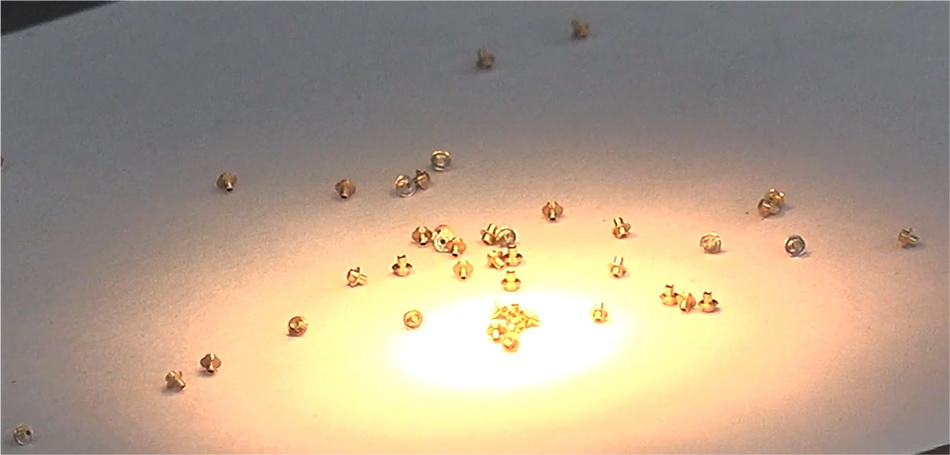

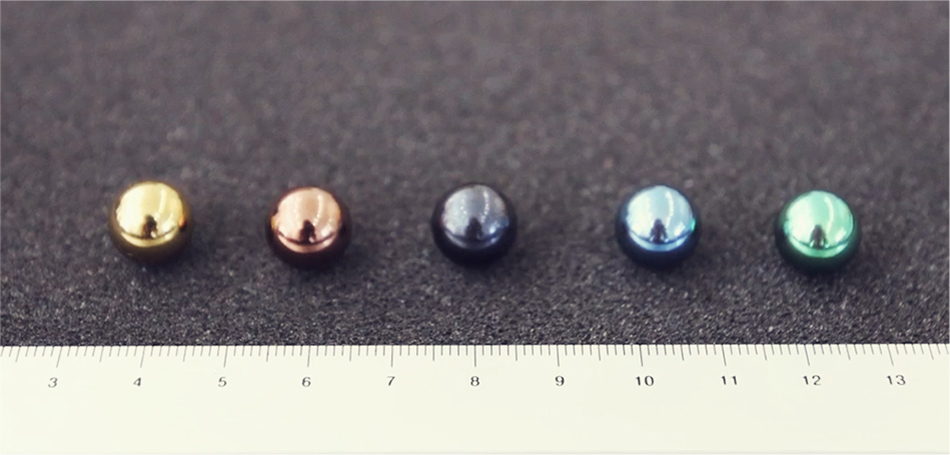

Sabae has become a major

production area that produces

about 90% of eyeglasses

frames manufactured in Japan by

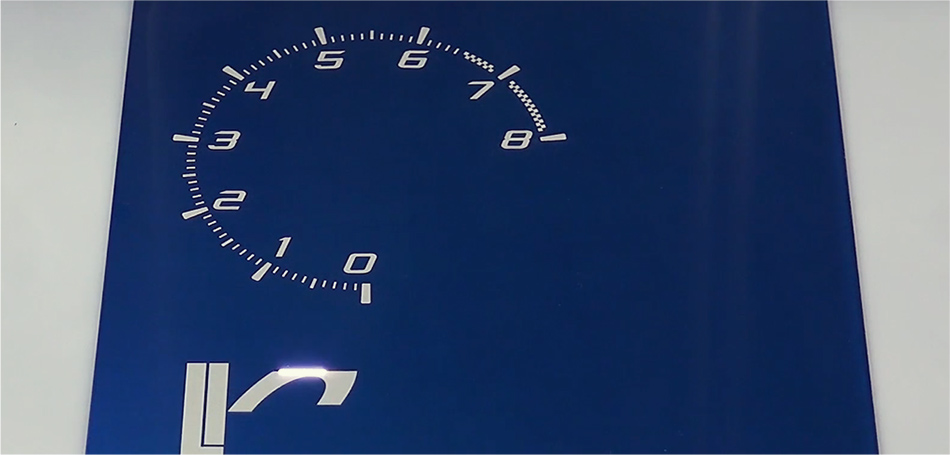

the success of world's first

productization of eyeglasses frame

made of titanium, establishment

of mass production system,

improvement of quality and

design and planning of

internationalization strategy.

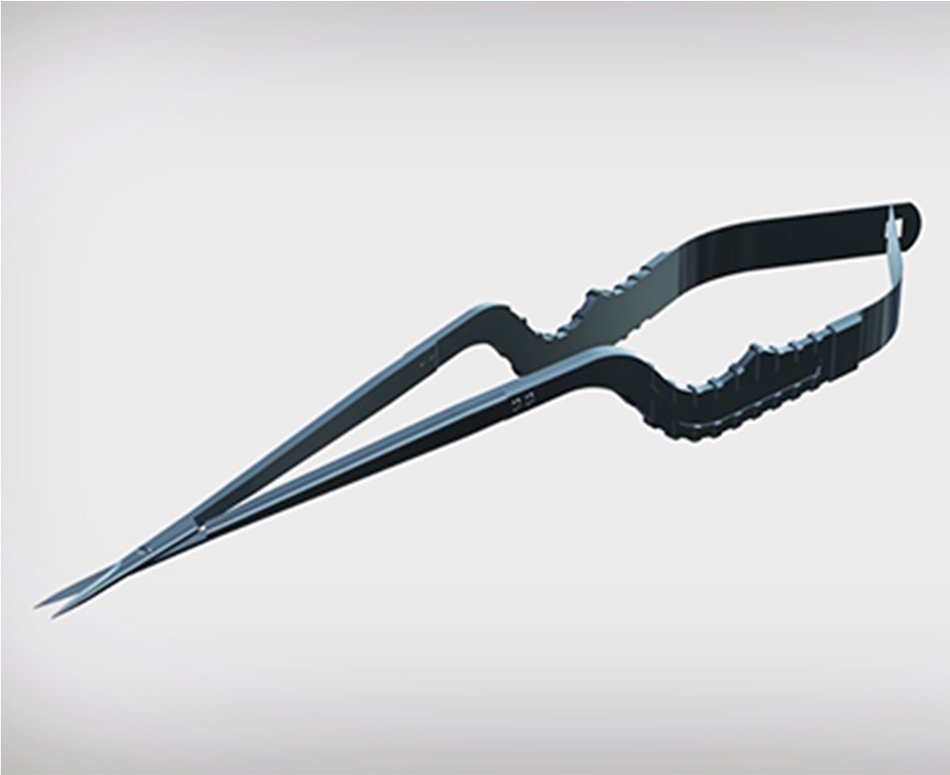

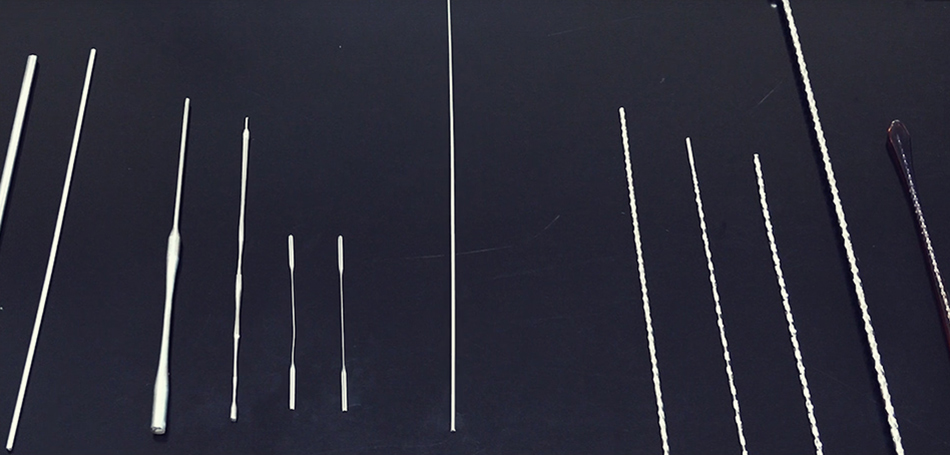

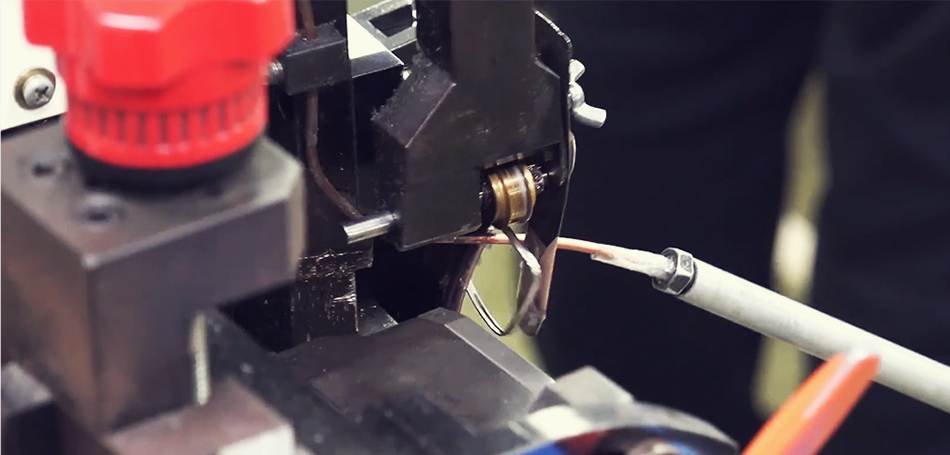

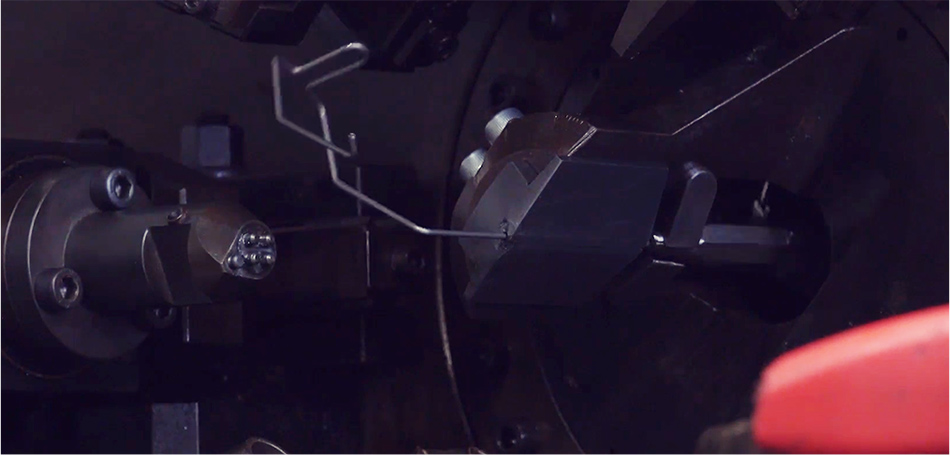

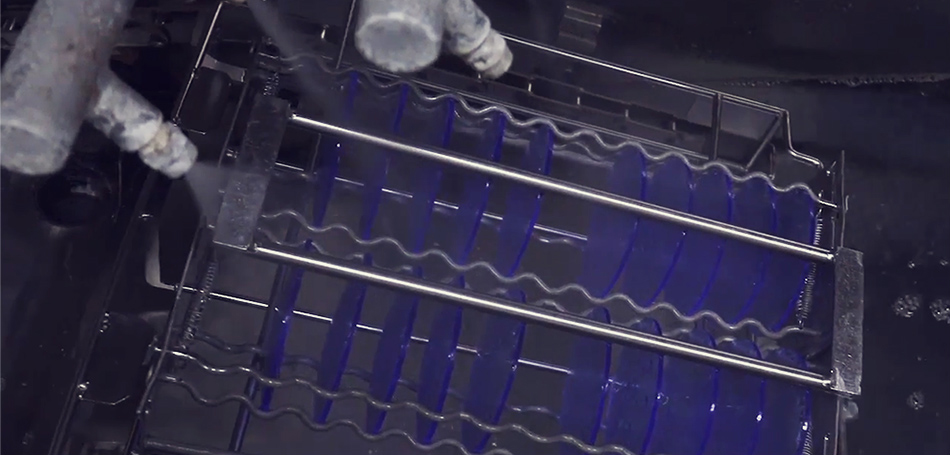

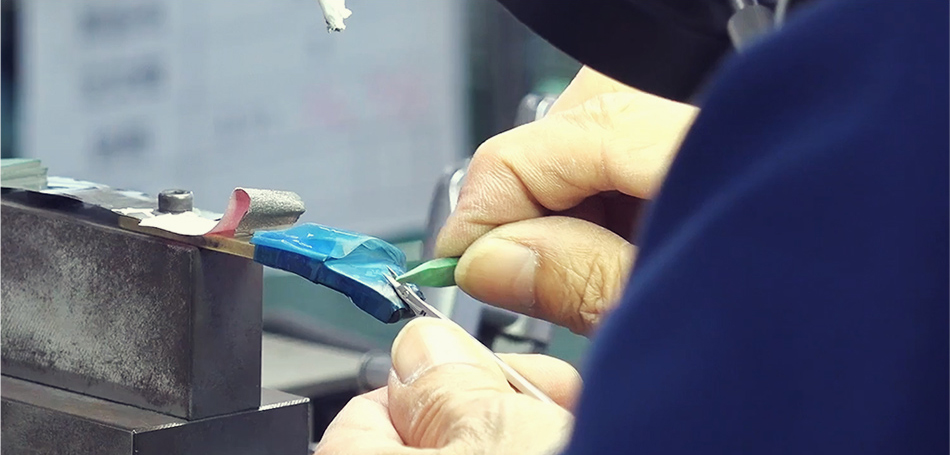

In recent years,

Sabae aims to revitalize

it’s industry by trying to expand

into different fields

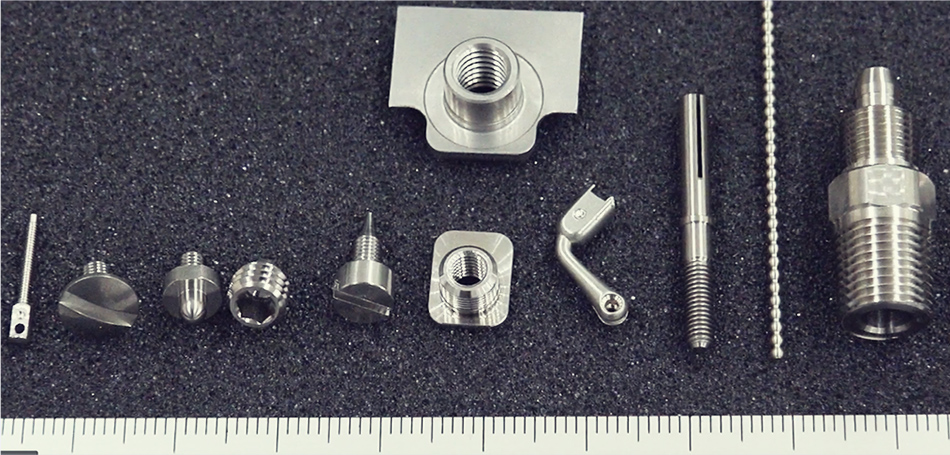

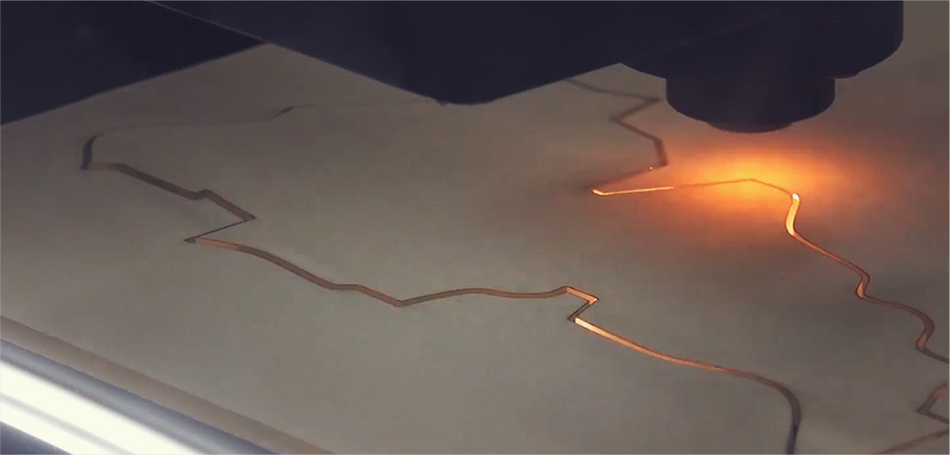

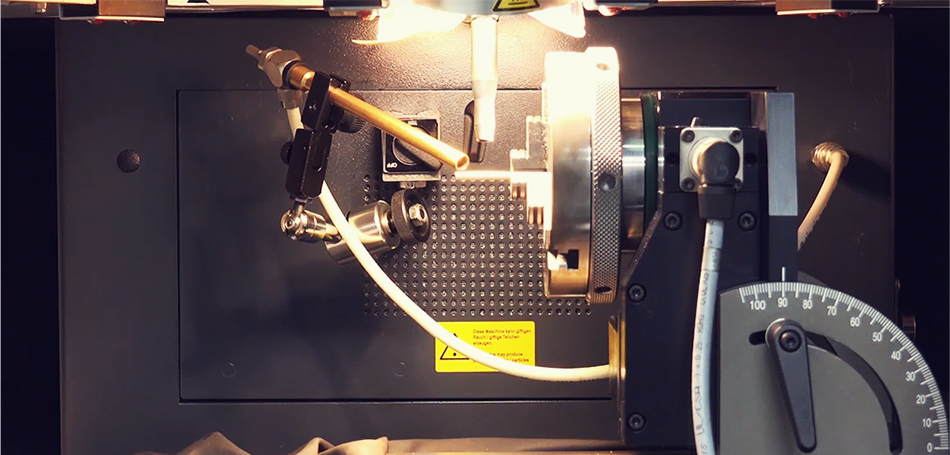

with our advanced

processing technology.